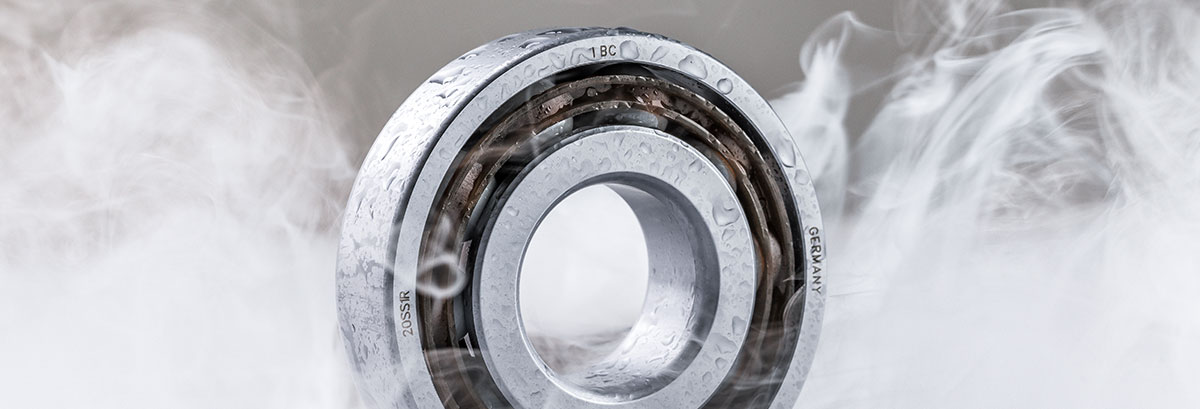

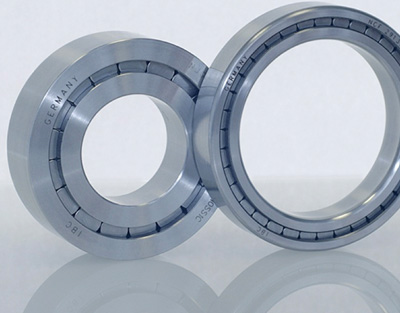

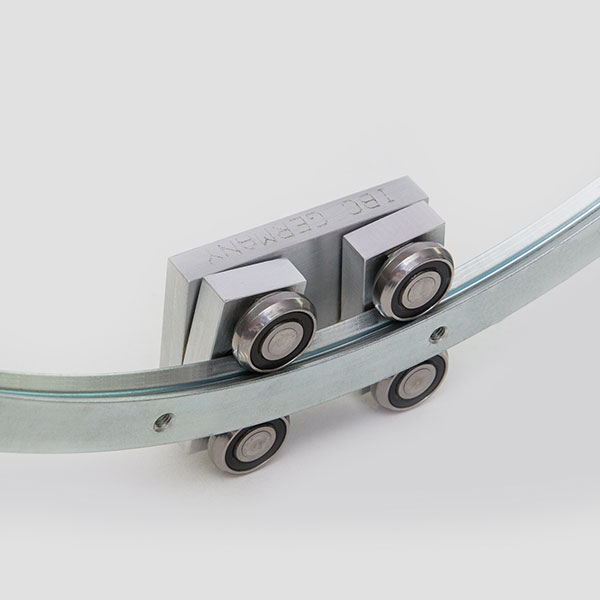

IBC 40° angular contact ball bearings

Single-row IBC 40° angular contact ball bearings are available in the 70, 72 and 73 series and are suitable for high external loads due to their internal geometry. Axial forces, which can only be accommodated in one direction pressure the rolling elements between the high shoulders of the inner and outer rings when under load. Due to the contact angle, the radial forces likewise cause an axial force that must be taken into consideration in the design.

- Extended Capacity and Advanced Application

- Extended Capacity and Advanced Application - series are characterised by:

- series are characterised by: