Welcome to IBC Wälzlager GmbH

IBC WÄLZLAGER GMBH continues the tradition of the Robert Kling Wetzlar GmbH founded in 1918. With an experience of more than 40 years IBC is acting worldwide in the field of bearing technology.

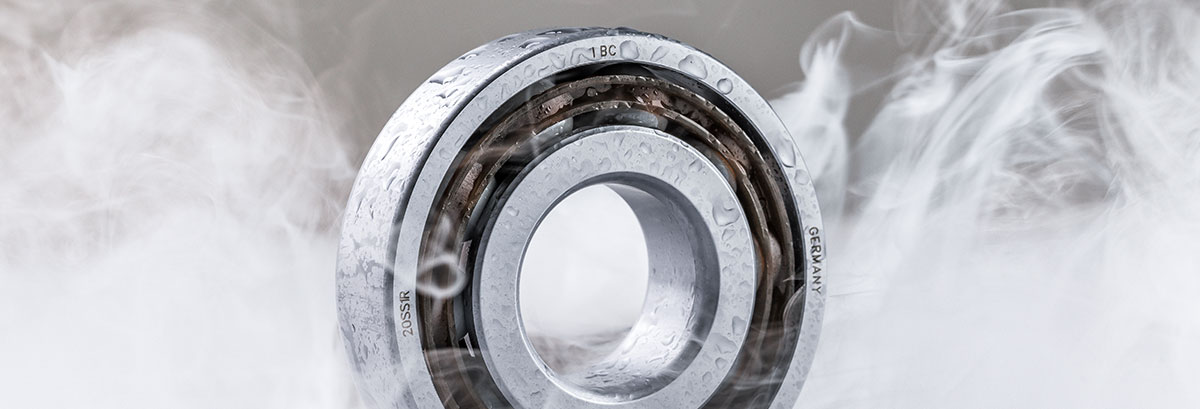

Continuously developed and optimized products show the technical competence, high productivity and performance of the production plants in Solms-Oberbiel (Germany), Asslar (Germany), Grenchen (Switzerland) and Aurangabad (India). A process-minded quality management system guarantees for an entire customer focus.

IBC is a reliable partner for special requests and solutions in the market of precision bearings and linear motion bearings. Our products convince through their long lifetime, user friendly handling as well as high cost-effectiveness. That is how the ideal combination of technology and economic efficiency is achieved. We on purpose put our focus on detailed, individual consultations, to work out the most effective solution together with the customer for his specific application.

- Extended Capacity and Advanced Application

- Extended Capacity and Advanced Application - series are characterised by:

- series are characterised by: